Load cells are a crucial component of electronic scales, and there are various types available. A thorough understanding of the characteristics of different kinds of load cells will help you choose the best load cell for your application.

The following content will detail the classification of load cells based on their working principles and design structures.

Classification of Load Cells Based on Working Principles

Strain Gauge Load Cells

These use bonded strain gauges. The strain gauge deforms under force, changing the resistance. The load is determined by measuring the resistance. Bending beam, shear beam, S-type, and compression load cells all belong to the strain gauge category.

Hydraulic Load Cells

These use fluid pressure (oil/water) to measure force. Their accuracy is lower than that of strain gauge load cells. They are ideal for measuring chemically corrosive liquids in industrial applications.

Pneumatic Load Cells

These measure force by measuring air pressure. They are suitable for explosive environments such as oil and gas plants and chemical plants.

Capacitive Load Cells

Force changes the distance between the capacitor plates. The load is determined by measuring the change in capacitance.

Piezoelectric Load Cells

Force generates an electric charge in piezoelectric materials, suitable for dynamic measurements.

Classification by Load Cell Design Structure

Single Point Load Cell

It can accurately measure the weight at a single location, even if the load is outside the center of the platform. Widely used in small weighing systems requiring high accuracy, such as platform scales, retail scales, and patient weighing scales.

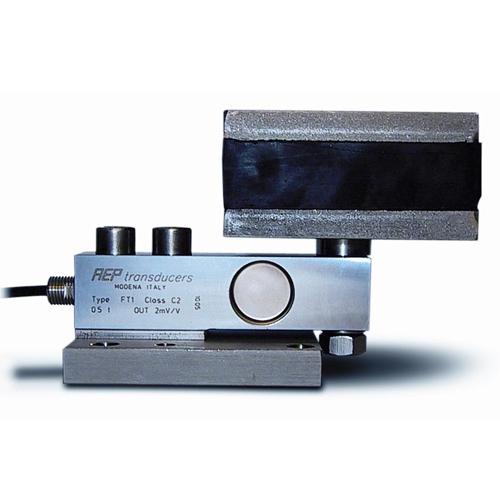

Beam Load Cell

Beam load cells include single-ended beam load cells, s-beam load cells, and shear beam load cells. Shaped like a small beam, strain gauges are mounted on the beam. When a load or force is applied, the beam bends slightly; the strain gauges detect this bending and change their resistance.

Beam load cells are made of stainless steel or alloy steel, are easy to install, economical, and suitable for medium-load weighing.

Compression Load Cell

Primarily used to measure compressive force, typically designed as a flat, button-operated, ring-shaped device to ensure stability and accuracy under downward loads. High load capacity, suitable for industrial weighing and heavy machinery monitoring.

Amplified load cell

Amplified load cells feature a built-in signal amplifier, eliminating the need for an external amplifier and simplifying installation. They are widely used in industrial automation, heavy-duty weighing, and high-precision material testing, as well as aerospace component testing.

OFweek supplies all of the load cell types mentioned above. Welcome to visit the OFweek website for more information.

Related Articles

没有评论:

发表评论