Proper installation of the load cell is crucial for ensuring a stable and accurate weighing system. The following guide details the correct steps for installing a load cell.

Preparation Before Installing the Load Cell Sensor

Determine the Installation Location

Choose a flat, stable surface for installation to avoid vibration or tilting, ensuring the sensor can accurately measure weight.

The mounting surface must be clean and free of oil, adhesive film, and other impurities. The base should be stronger than the sensor itself to prevent deformation from impact, which could affect measurements.

If multiple load cells need to be installed, adjust the base to ensure all sensors are on the same horizontal plane. A level can be used for adjustment to ensure even load distribution.

Prepare Installation Tools

Prepare appropriate screws, nuts, washers, or brackets, or use the original installation tools provided with the load cell, depending on the sensor size and load requirements.

For high-capacity load cells, it is recommended to use lifting equipment for transport to avoid damage from impacts or drops.

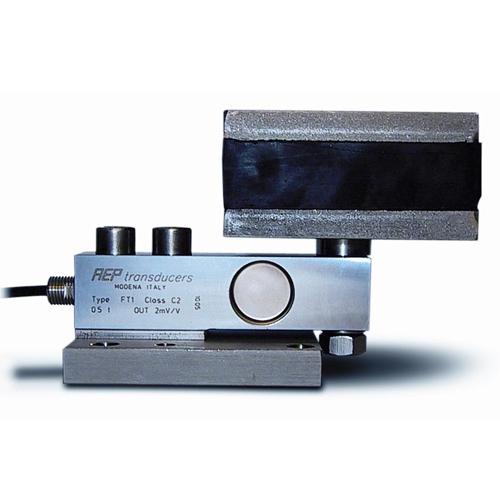

Begin Installing Your Load Cell Sensor

Align the Load

Keep the load and the load cell's axis aligned to ensure even force distribution on the load cell.

Bolt Fixing

Use a calibrated torque wrench to tighten the bolts to the manufacturer's specified torque, avoiding overtightening or loosening.

For single ended beam load cell, only the sensing end needs to be fixed; the other load end should remain unsecured to allow for elastic deformation under load.

Connecting Cables and Power Supply

Connect the power and signal cables to the reading device (e.g., PLC, computer) according to the instruction manual. Ensure correct interface (e.g., analog output, digital output, or wireless interface) to avoid poor contact or short circuits.

Pay attention to power supply stability; it is recommended to use the sensor's rated voltage to avoid overvoltage damage.

Calibration and Adjustment

Zero-point calibration: Adjust the reading to zero under no-load conditions. Test the sensor response with objects of different weights to verify reading accuracy and stability.

Sensitivity Adjustment: Place an object of known weight to check if the output matches; adjust parameters if necessary. If there are large variations in ambient temperature, temperature compensation calibration is required.

Proper installation of the load cell sensor is crucial for maintaining accuracy, safety, long-term system stability, and extending system lifespan. The above is a detailed guide to the installation of load cells, which we hope will be helpful to you.

Welcome to OFweek! We supply a variety of high-quality load cells and electronic components for your inquiries.

Related Articles