True RMS Voltage Transducers can be categorized as single-phase, three-phase, and multi-phase based on their application and output signal type.

The phase of a true RMS voltage transducer refers to the angular relationship between the voltage and current waveforms in an AC circuit. Different phases also have different application areas.

Single-phase true RMS voltage transducers: Operate using a single AC waveform, stepping up or down the voltage based on lower power requirements.

They have a relatively simple structure and a relatively low cost. They can measure the RMS voltage of a single AC line and are primarily used to monitor the supply voltage quality in residential environments, small offices, and household appliances and lighting systems.

|

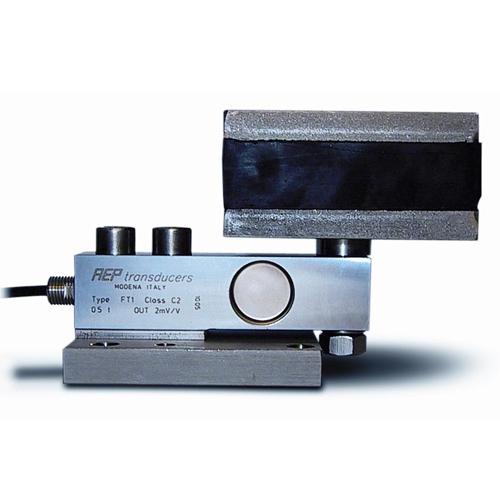

| CR4570 true rms ac voltage sensor |

Three-phase true RMS voltage transducers: They can simultaneously manage three AC waveforms and have a more complex structure.

They are primarily used to monitor heavy-load systems such as distribution systems, switchgear, and substations.

Multi-phase true RMS voltage transducers: Designed specifically for multi-phase networks, they are characterized by a highly complex structure. Used for specialized or high-end systems requiring more than three phases or multi-line monitoring.

OFweek supply a wide selection of true RMS AC voltage transducers online

Visit the OFweek Mall and, in the Sensors section, you can quickly find a wide variety of single-phase and three-phase true RMS AC voltage transducers. These voltage sensors are from professional brands, and you can negotiate pricing with the vendor online one-on-one. There's no need to worry about middlemen profiting from the price difference.

Related Articles

Common Categories of True RMS Voltage Transducers

What is a true rms ac voltage transducer?