Load cells are crucial components of various load systems, determining the accuracy and efficiency of load or force measurements. They are widely used in industrial automation, aerospace, and medical fields.

If you are struggling to wholesale load cells for your load system upgrade, please read the following to help you quickly determine the appropriate load cell.

5 Factors to Consider When Choosing a Load Cell

Determine the Required Load Cell Type

There are many types of load cells, each with its specific advantages and applications. You need to clearly define the type of force your load system will measure, such as tension, compression, shear, or bending. Accurately identifying the force type will help you quickly determine the appropriate load cell. If you are unfamiliar with the classification of load cells, you can read the previous articles on types of load cells.

Determine the Required Measurement Range

Determine the required load cell range for your load system. Ideally, choose a capacity 20% to 30% higher than the maximum expected load to avoid overload. Size is also important; it needs to be perfectly compatible with your load system.

Accuracy Requirements

For load systems used in medical and aerospace applications, high-precision load cells are required to ensure the reliability and safety of measurement results. In general industrial or logistics weighing scenarios, load cells with higher cost-effectiveness and moderate accuracy requirements can be selected based on actual needs.

Application Scenarios

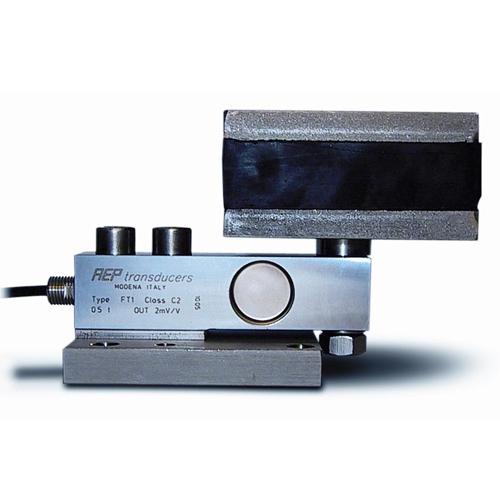

The working environment affects the lifespan and accuracy of load cells. For applications involving water, corrosive substances, or high pressure, waterproof, explosion-proof, and corrosion-resistant load cells should be selected. The UPFT1 tank load cell maintains high performance even in harsh environments, making it ideal for such application scenarios.

Wholesale Load Cells from Professional Channels

Finally, it is advisable to wholesale load cells from professional platforms to ensure product quality and after-sales service.

Following these principles when wholesaling load cells will help you efficiently select the best load cell for your application.

OFweek is a professional platform providing high-quality electronic components, supplying a complete range of load cells, and offering excellent after-sales and logistics services. Welcome to visit and inquire; we provide professional pre-sales consultants.

Related Articles

What are the Types Of Load Cells?